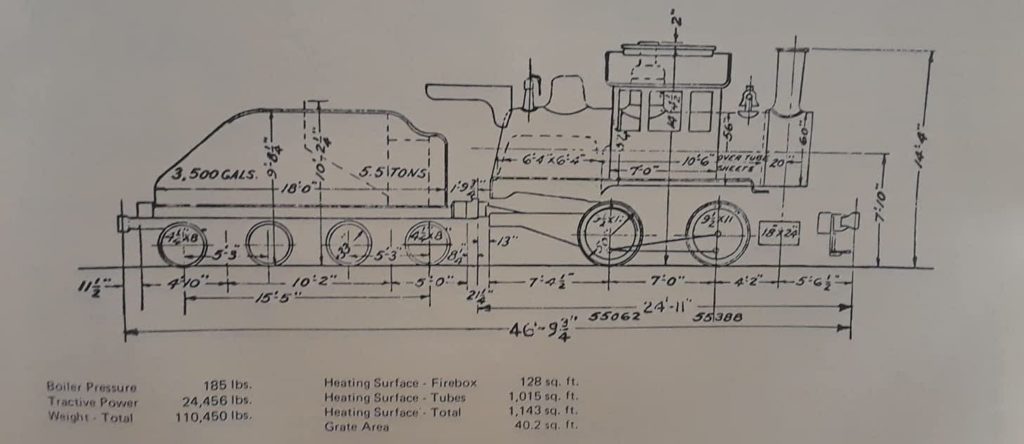

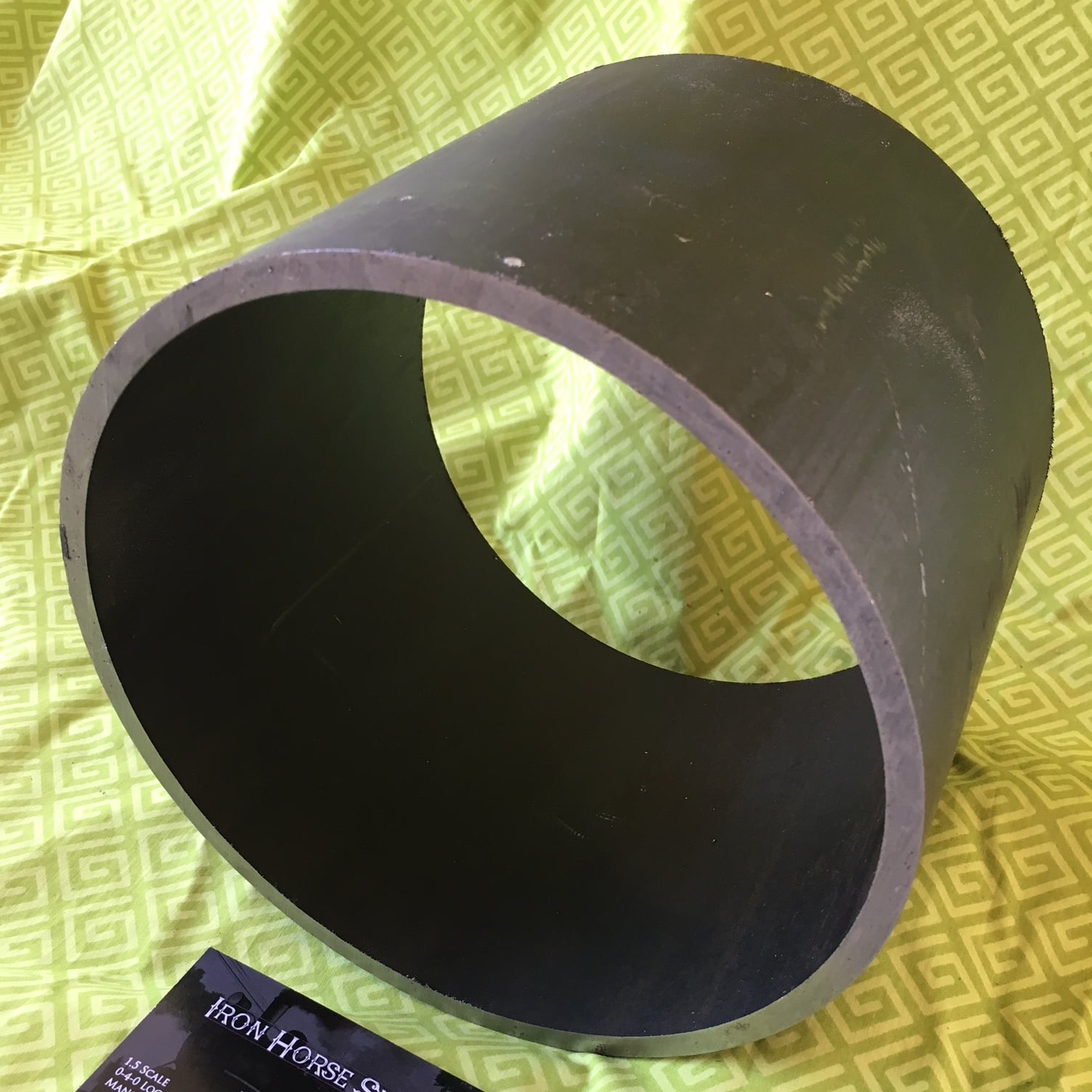

This engine is a model of the Reading Company’s 0-4-0 switcher. It has been scaled down to 1-1/2 inch to the foot scale from the original blue prints. The initial four engines were built by four live steamers: Elmer Nuskey, Ben Nixon, Gil Ritenburg, and Bud Kremers. This engine has proven to be an excellent steaming locomotive as well as a mechanically sound design. The prints are drawn clearly and the castings are top quality. Castings for the engine are made from either iron or bronze. Other components are either sheet brass or cold rolled steel.

The engine has proven to be a good first project. A builder can construct it with tools such as an 8 inch lathe; a small bench mill, a drill press, plus the usual hand tools. One is not limited to the 0-4-0 design. The builder has the option of building an 0-6-0 or stretching the frame to a 2-8-0 configuration and relocate the cab in a more conventional rear position.

Specifications

- Scale: 1-1/2 inches to the foot (1/8th scale)

- Engine Height: 23 inches

- Tender Length: 31-1/4 inches over beams

- Tender Width: 15 inches

- Overall Locomotive Length: 75 inches

- Engine & tender weight: 350 pounds

- Track Gauge: 7-1/2 or 7-1/4 inches

- Bore & Stroke: 2 x 3 inches

- Valve Gear: Stephenson

- Driver Diameter: 6-1/4″ inches

- Fuel: Coal or LPG

- Working Pressure: 120 psi

- Minimum Track Radius: 15 feet

Photos

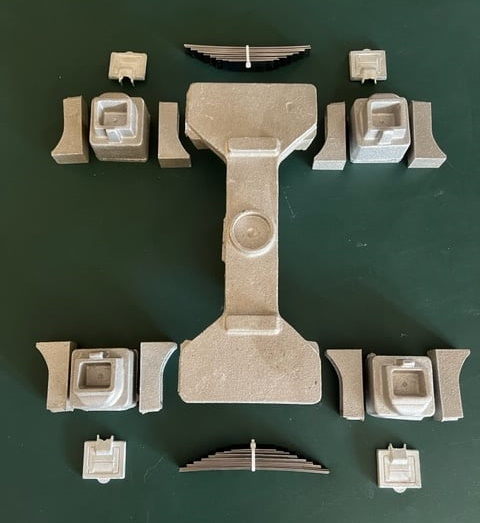

Parts

Here you can view many of the parts for this model. For the complete list of parts and pricing, please view the Ordering/Pricing page.

This overview picture displays the following parts left to right: A5-RB-101 Rear Buffer, A5-D Drive Wheel, A5-CP Coupler Pocket, A5-JSE Journal Spring Equalizer, A5-BSB Brake Shaft Bearing, A5-BCS Brake Cylinder Spring and A5-BCR Brake Cylinder O-Ring in bag, A5-BC-100 Brake Cylinder, A5-BCFH-101 Brake Cylinder Front Cover, A5-BCC-102 Brake Cylinder Lower Cover, A5-SY Spring Yoke, A5-EA Equalizer Anchor, A5-RB Rocker Box, A5-GY Guide Yoke, A5-ES Eccentric Strap, A5-E Eccentric, and A5-FB Front Beam.

This overview picture displays the following parts left to right: A5-CH Crosshead, A5-SV Slide Valve, A5C-103 Steam Chest Cover, A5-SC-100 Steam Chest, A5-CYL Cylinder, A5-RH-102 Rear Cylinder Cover, A5-JB Journal Box, A5-S Saddle, A5-M-100 Manifold-Cylinder Spacer, A5-RH-101 Front Cylinder Cover, and A5-TS Tender Step.

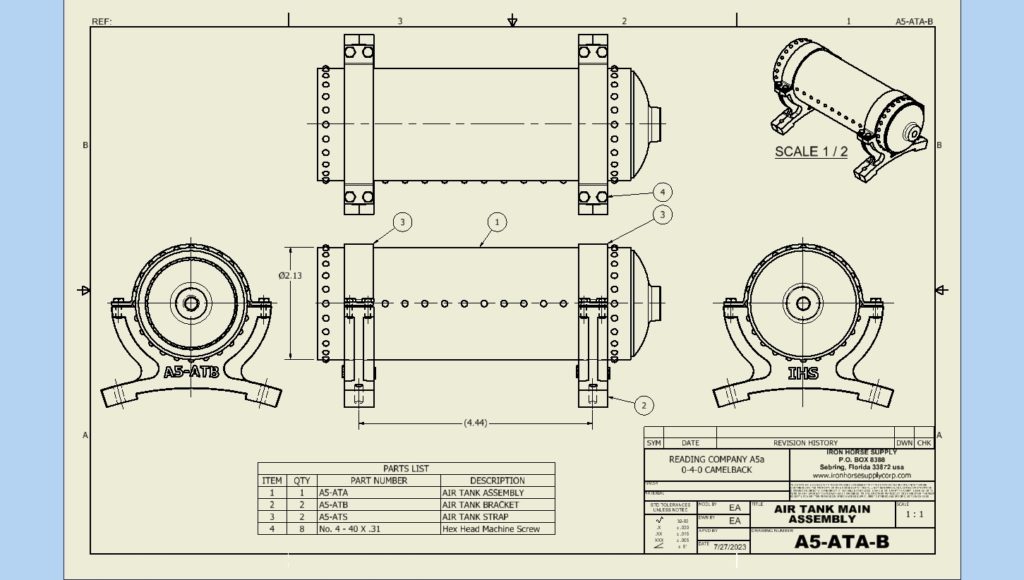

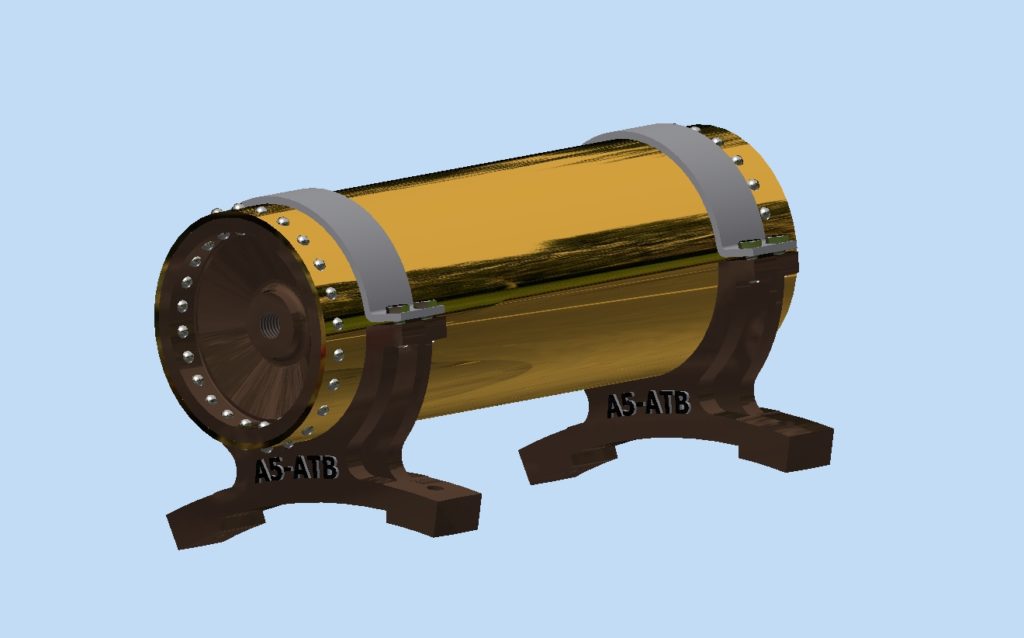

Air Tanks Ends & Brackets – These castings are for the two air tanks that sit above the boiler on the Camelbacks. They can be used for other mounting positions as well. The length of the tank can be whatever you choose to cut your stock to. On the A5a, they work out to approximately 6″ long. When ordered, drawings will be included, covering not only the casting(s) machining but also the tank and straps.