Your cart is currently empty!

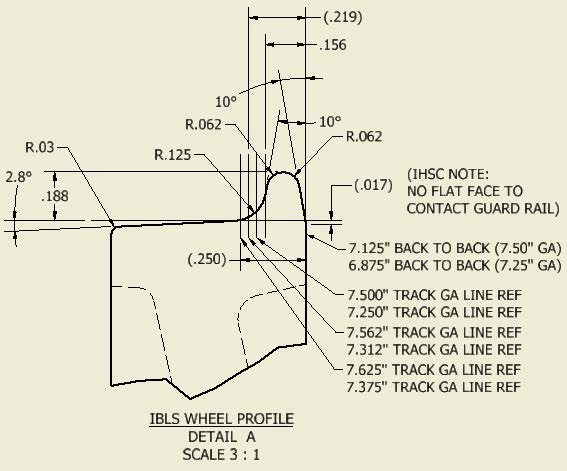

IHSC Wheel Standard

IBLS is the current recommendation for wheel flange profiles. Iron Horse Supply Corp has been reviewing rail wear patterns along with wheel wear. Another review is how the profile(s) fits with the various current rail heads supplied. IHSC has come up with a slight variant to the IBLS flange profile after reviewing above considerations and the other wheel flange profiles provided by other wheel suppliers.

IBLS Profile

IHSC Profile

Discussion

- As the wheel set rides closer to the outside rail in a curve, the Gauge Radius R.156 (IHSC) will cause the wheel to ride higher quickly, thus a larger wheel circumference than the inside wheel circumference. Resulting change will cause the wheel set to navigate the curve without contacting the flange itself. Of course, on a very tight radius, the flange does come into use.

- On sharp(er) cornered rail heads, this R.156 156 (IHSC) works quicker than the R.125 (IBLS).

- This larger R.156 156 (IHSC) also allows for worn rail heads and wheel wear, while still functioning.

- Some new wheels are offered at R.094, though do work, Do note this radius is already matching some rail head radiuses, thus, putting the flange to work in all curves (ultimately wearing of the rail head and wheel).

- Another item to note is that the back taper on the IBLS profile does not help much with guard rail contact. See below.

This is why some tracks are now using guard rails that are ¼” higher than the rail head. (of course, there are generous lead angles on each end of these guard rails). Yes, some wheels supplied do offer a shorter back taper to present a flat surface.

The IHSC profile back face offers even more of a flat contact surface:

Disclaimer: IHSC wheel profile is preliminary and unproven.